4 Simple Techniques For American Plastics

Wiki Article

American Plastics Can Be Fun For Anyone

Table of ContentsNot known Details About American Plastics American Plastics Can Be Fun For EveryoneSome Ideas on American Plastics You Should KnowSome Known Factual Statements About American Plastics Everything about American Plastics

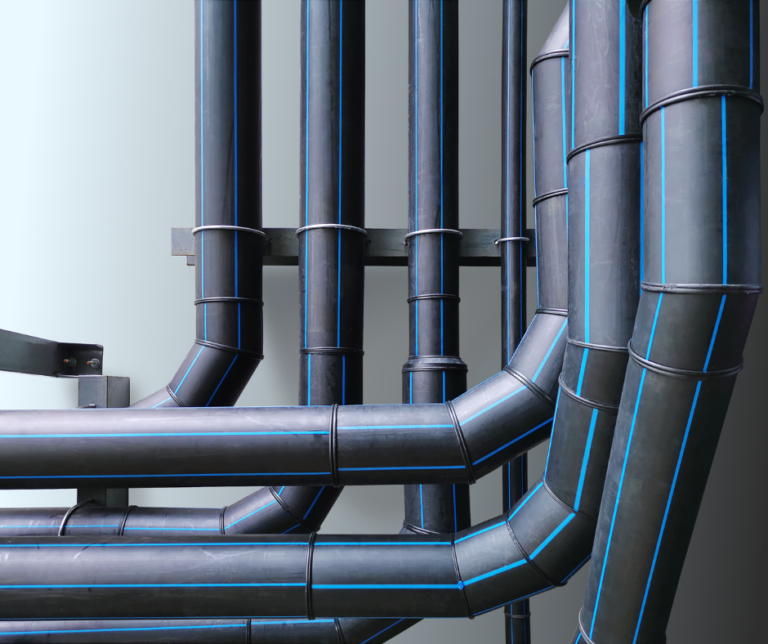

Recognizing these factors will certainly permit you to make informed choices when selecting the most suitable pipe for your job. The material composition of the HDPE pipe plays a critical role in determining its PSI rating. HDPE pipelines are made from high-density polyethylene, a thermoplastic recognized for its strength and durability.Different grades of HDPE might have varying PSI scores, so it is necessary to take into consideration the material structure when selecting a pipe for your particular needs. The diameter of the HDPE pipe is an additional essential element that affects its PSI score. Larger diameter pipelines normally have higher PSI rankings, as they have much more material and surface to endure stress.

The wall surface density of an HDPE pipe likewise affects its PSI ranking. Thicker wall surfaces supply boosted toughness and resistance to stress, permitting the pipe to deal with greater PSI degrees.

It is necessary to think about the optimum operating temperature of the pipe and pick a PSI ranking that can manage the anticipated temperature array - https://profiles.delphiforums.com/n/pfx/profile.aspx?webtag=dfpprofile000&userId=1891266661. The PSI score of HDPE pipelines is figured out with extensive screening and accreditation processes. Understanding how these scores are determined will provide you with confidence in the accuracy and integrity of the chosen pipeline

An Unbiased View of American Plastics

Organizations such as the American Society for Testing and Products (ASTM) and the International Company for Standardization (ISO) have actually established details examinations to evaluate the efficiency and toughness of HDPE pipes. These tests step aspects such as ruptured stress, tensile strength, and long-term hydrostatic strength to identify the ideal PSI score.This test includes subjecting the pipeline to enhancing inner pressure until it stops working. The pressure at which the pipeline bursts identifies its optimum PSI score, showing the stress it can withstand without failing. Long-lasting hydrostatic stamina testing examines the pipe's capacity to withstand stress over a prolonged duration. This test entails subjecting the pipeline to a constant stress for an extensive period, replicating real-world conditions.

HDPE pipelines with higher PSI ratings are naturally extra long lasting and resistant to deformation under stress. Texas hdpe pipe manufacturer. Picking pipelines with greater rankings guarantees they can hold up against unexpected pressure rises or outside loads, lowering the risk of pipeline failure and the requirement for frequent replacements. HDPE pipelines with greater PSI ratings often have boosted resistance to ecological factors such as UV radiation, chemicals, and abrasion

The Best Strategy To Use For American Plastics

By selecting HDPE pipelines with greater PSI rankings, you can guarantee the security of your system and workers. These pipelines are built to handle high-pressure circumstances, minimizing the risk of leakages, ruptureds, and various other dangerous cases that can threaten individuals or residential property. Spending in HDPE pipes with greater PSI scores might call for a greater in advance price, yet it supplies long-lasting expense financial savings.

These pipelines ensure the safe and efficient circulation of drinkable water from the resource to the consumer. HDPE pipes with appropriate PSI ratings are extensively made use of in gas circulation networks. They can securely deliver gas or various other gases from the resource to residential, business, and industrial areas, making certain dependable and effective gas supply.

Some Known Details About American Plastics

They can manage the pressure needed for effective irrigation and watering of lawns, yards, parks, and sports fields (hdpe pipe suppliers Midland TX). HDPE pipelines with high PSI rankings are ideal for transporting various industrial chemicals. They can take care of the pressure needs and withstand chemical deterioration, ensuring the secure and effective transport of chemicals in commercial settings

Appropriate installment is important to make best use of the performance and longevity of HDPE pipelines. Adhere to these standards when installing HDPE pipes with details PSI scores.

Select the ideal jointing approach based on the PSI rating of the HDPE pipe. Select installations and devices that are suitable with the PSI rating of the HDPE pipe.

Some Ideas on American Plastics You Need To Know

After installation, perform stress screening to make sure the stability of the HDPE pipeline system. Follow market standards and standards to carry out the ideal stress tests, such as hydrostatic or pneumatic testing, to verify the system's capability to handle the necessary pressure. Appropriate backfilling and compaction around the mounted HDPE pipelines are important to give security and secure the pipes from exterior tons.Report this wiki page